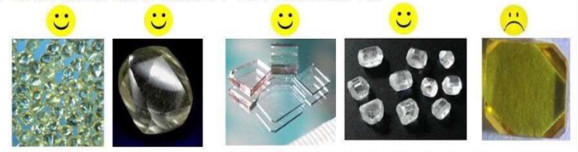

| Message: | 1. Selection of Diamond blanks materials: natural crystal; CVD and HPHT monocrystal

diamond cutting tools

❉ The color of natural crystal and pureness are not necessary to be good, the worst dark puce blanks can be selected.

❉ At present, the man made noncrystalline have to reach some standards, cutting tools made welded with the transparent CVD, after the surface modification, is work life can be prolonged.

2.The selection of crystalline surface: no matter choose which crystal blanks for cutting tools, there must be a 110 facet for the tool face.

❉ This cutting face crystal direction selection, after the surface modification, the work life is roughly the same. However, the rake angle -35°±10°, and the tool face is close to 110 crystal face, performance will be better.

❉ The domestic 100 facet and 100 sides yellow crystalline blanks for the cutting tools should be cut apart diagonally. And then design the 110 crystal face to be the rake face and the flank face or make the cutting tool face among the 110 side.

3.Surface modification technical principals:

❉ processing residual stress relieving

❉ damaged layer of cutting surface repairing

❉ cutting tool surface hardness improving

1) the process is the same to conventional metal cutting tools by rounding a removal of tens of nanometers

2) as for the edge passivating, at present, we can accurately control the sharpness from 20mm to 50mm.

3) the rounding of the tool face can eliminate and relief the machine pressing and grinding chipping or cracks.

4) different from the surface modification technology, the edge passivating technology is not concerning the tool face crystalline selection.

5) Currently, the edge passivating of one cutting tool need 2h, and the service life is under assessment

If you have any question about diamond cutting tools , please check here: www.moresuperhard.com

TEL: 0086-371-86545906 e-mail: anna.wang@moresuperhard.comAre you interested in tool |

my account

my account

log out

log out

my account

my account

log out

log out