| Message: | SG ( Sol Gel ) Grinding Wheel

Introduction of SG grinding wheel :

Ceramic abrasives prepared by sol-gel method is a kind of sintered abrasive , grain size is tiny, only 100- 500nm, hundredths of the size of ordinary corundum abrasive crystal. SG abrasive is high purity, ceramic aluminum oxide abrasive with a submicron crystalline structure deprived from a seeded gel sintering process. The grinding tools made of ceramic abrasive have the characteristic of long life , good self- sharp ability, high cutting efficiency, and low possibility of workpiece burning.

The parameters of Ceramic abrasives :

Main chemical composition(typical value) :Al2O3 (99.22%)Na2O(0.08%)

Physical properties(grain size 60):Density 3.90(g/cm³)Bulk density 1.82(g/cm³)Crystal size 0.15 (μm)

The offerable grain size:24-180#

Code:SG

Applications of SG grinding wheel :

* Precision grinding for unhardened and hardened steels,such as cast iron,carbon steels, alloy steels, and tool steels, etc.

* Internal grinding roller bearings, cylinders, compressor parts, gear parts, hydraulic and pneumatic cylinders etc.

* Grinding the crankshaft and camshaft of the engine and transmission of the car ; worm gear grinding .

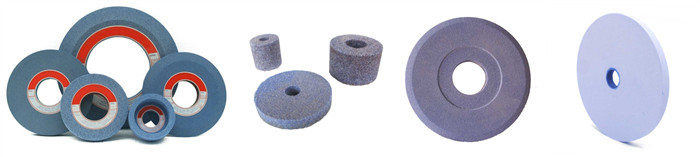

SG grinding wheel for roller SG grinding wheel

SG grinding wheel SG grinding wheel

Advantages of SG grinding wheel:

* Grinding wheel made of ceramic abrasive with has a higher durability and longer life, which is 5-10 times than the grinding wheel made of common corundum.

*Sharp grains , good cutting ability, and high grinding efficiency .

* Good self- sharp ability, microcrystalline structure Benefits ;

* Very good cutting capability, sharp grains;

* High removal rate& extended wheel life .

anna.wang@moresuperhard.com

|

my account

my account

log out

log out

my account

my account

log out

log out