| Message: | Production Line introduction

Aluminum WABE panel production line is completely designed and manufactured by BEIERTEC. Through a serial online process, this production line is able to laminate three thickness and alloy of aluminum materials into one composite panel. With BEIERTEC technology, this line is adopted modular design which are able to produce WABE panel and A2 non-combustible APC panel in one line. It is also adopted full automatic control system to improve production capacity and save labor cost. By the optional wireless monitor system, you are even able to check manufacturing status anywhere.

Process method

The whole process is including 4 modules: washing, coating, laminating, cutting.

Washing module: to clean the surface of raw aluminum coil in order to ensure the perfectness of down process for coating.

Coating module: to coat thermos sensitive polymeric film on both side of aluminum coil at high temperature. this module will protect the surface plainness as well as transform film to viscose for composite.

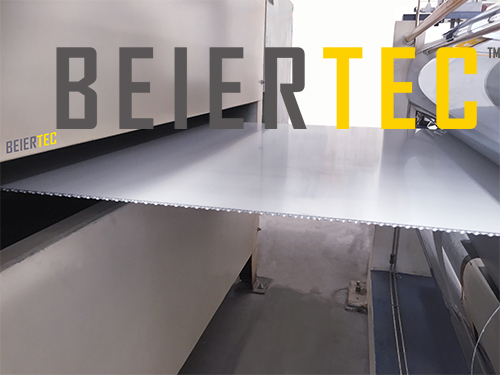

Laminating module: to emboss the core layer by BEIERTEC WABE pattern, then laminating with the top, back aluminum layers synchronous into one composite board and convey to next process.

Cutting module: the finish produce will be automated cut with the need s of customers. |

my account

my account

log out

log out

my account

my account

log out

log out