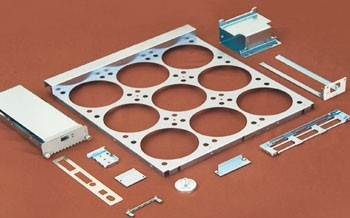

| Message: | 1.Hop Cheong Metal Product Fty. Ltd.is a Stamping workx35a53ban,metal hardware stamping partsin one large multi-functional integrated modern enterprise,and devote the high-quality Metal die stamping factory and first-class service for the masses of customers.

2.The advantage of Hop Cheong Metal ProductFurniture metal stamping partsis that it can provide more professional and thoughtful solutions timely and accurately according to the actual needs of customers.At the same time, Our company follow the latest developments on System.String[], and establish long and steady partnership relation with many well-known enterprises in the same industry , to provide customers with the most professional, advanced Metal stamping parts.Details:4.Punching workpiece is the forming method of the workpiece (punching workpiece) which is produced plastic deformation or separation by applying external force to sheet, strip, tube and profile by press and die, so as to obtain the required shape and size of workpiece (punching workpiece). Stamping and forging both belong to plastic processing (or pressure processing), collectively known as forging. The blanks are mainly hot-rolled and cold-rolled steel sheets and strips. Compared with castings and forgings, punching workpieces have the characteristics of thin, even, light and strong. Stamping work can produce workpieces with stiffeners, ribs, undulation or flanging that are difficult to manufacture by other methods to increase their rigidity. The precision of workpiece can reach micron due to the use of precision mould. and the invention has the advantages of high repetition precision and uniform specification, and can punch out the hole socket, the boss and the like. The stamping process is mainly classified according to the process, and can be divided into two types: the separation process and the forming process. The separation process is also referred to as punch cutting, and the purpose of the invention is to separate the stamping |

my account

my account

log out

log out

my account

my account

log out

log out