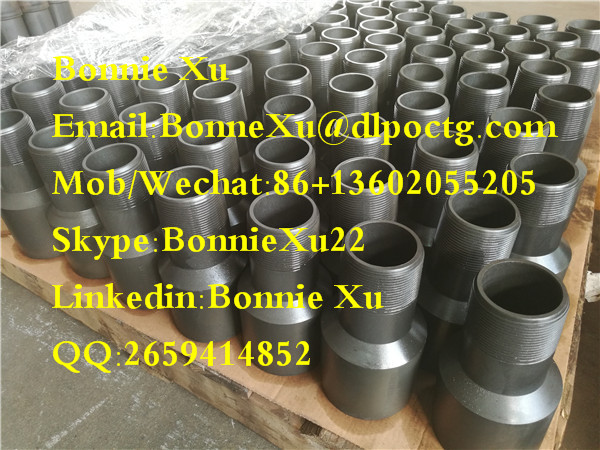

| Message: | premium connection nipple joint

Advances in the petroleum industry, especially drilling and production technologies, have promoted research and development of special threaded casings. With the development of deep wells, ultra-deep wells, high-pressure oil and gas wells, heavy oil thermal recovery wells, heavy corrosion wells, directional wells, etc., more and more stringent technical requirements are imposed on oil casing. API round thread and partial trapezoidal thread joints can not meet the requirements of oil and gas wells with harsh environmental conditions in terms of air tightness, connection strength and corrosion resistance, forcing people to research and develop special thread joints with more reliable performance. The research and development of special threaded oil casings started abroad in the late 1940s, put into use in the 1960s, and were widely used in the 1980s. At present, some new buckle types are introduced every year.

In the special thread research and development, small-scale mini experiments, full-scale evaluation tests, and finite element and experimental stress analysis techniques are mainly used. Breakthroughs have been made in the following aspects: 1. Sealing technology, through elasticity and metal sealing structure The design is that the airtight resistance of the street reaches the yield pressure in the tube. Second, the high connection strength greatly improves the stress distribution of the joint through the design of the thread buckle. The coupling strength of the coupling connection reaches or exceeds the strength of the pipe. Problems with slippage.

Contact;BonnieXu

Mob/Wechat:86+13602055205

Skype:BonnieXu22

Linkedin:BonnieXu |

my account

my account

log out

log out

my account

my account

log out

log out