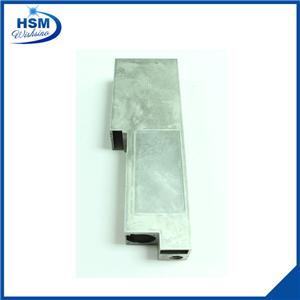

| Message: | Looking something like a drill press, a milling machine uses a cutting tool that moves in all three dimensions,can be used. removing material to achieve the desired part shape. The cutting tool usually rotates about an axis that is perpendicular to the table that holds the material to be cut. A cutting tool protrudes down from a rotating spindle. A block of material is placed on a moving table below the cutter. While the cutting tool turns, a computer controls the vertical (Z axis) motion of the cutter and the horizontal (X and Y axis) motion of the block of material. The cutter is guided to move through the material, removing portions to create shapes. Additionally, the material can be turned to various orientations in the middle of the process and cutting tools of various shapes Tolerance: 0.003~0.01mmIntended Application:Armatures/ Axles/ Bolts/ Bushings/ Coupling Shafts/ Dowels/ Driveshafts/ Fasteners/ Handles/ Housings/ Knobs/ Needle Valves/ Nozzles/ Pins/ Pivot Rods/ Precision Electronic Hardware/ Punch Blanks/ Shafts/ Shanks/ Sleeves/ Spacers/ Terminals/ Valve Bodies/ Valve Stems/Features Possible:Turning/ Boring/ Broaching/ Cross tapping/ Custom tapering/ Drilling/ Eccentric Holes/ External Splining/ Grinding/ Knurling/ Milling/ Slotting/ Splining/ Thread milling/ Threading external/ Threading internal/ Thread whirling/ Pointing/ Reaming/ TappingMaterials:Alloy Steels (4130, 4140)Aluminum (2011 6061-T6, 2024)BerylliumBrassBronze AlloysCarbon Steel (12L14, 1215)CarbideCopperNickelStainless Steel (303, 304, 316, 321, 303SE, 420, 440C, 17-4) url:http://www.china-moulders.com |

my account

my account

log out

log out

my account

my account

log out

log out