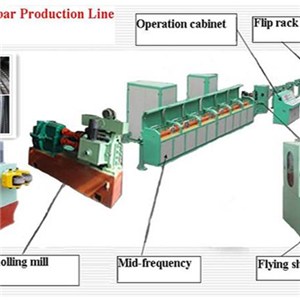

| Message: | 1. The whole plan description: .........Raw material type : Q235、Q215,Website:http://www.jindimachine.com, low carbon, and middle carbon steel.........Input diameter scope: 6.5-16mm.........Output diameter scope: 5-14mm........ Speed of produced finished product ......... 2-3m / s..........Capacity: 20-80T/shift(One shift =8 hours) 2. Technical Process:Layout 1 Layout 2 3. Technical specification of cold rolled ribbed production line for 2 ribbed steelItemSmall type LLZ210Medium type LLZ228Medium type LLZ250Large type LLZ285UnitRaw materialΦ6.5-10Φ6.5-12Φ6.5-14Φ10-16mmRoller DiameterΦ210Φ228Φ250Φ285mmPower55-7575-110110-132130-160KWCenter distance between gears650650650700mmRolling speed1.5-21.5-31.5-2.52-3m/sCutting length1.5-121.5-121.5-121.5-12mMotor of flying shear 5.57.51115KWProduct specificationΦ5-8Φ5-10Φ5-12Φ8-14mmOutput20-3525-5040-7060-80T/Shift The whole set of 2 ribbed cold rolling line were composed with: 1. Pay-off machine2. Scaling and reducing machine(Dephosphorization and reducing the diameter)3. Rolling mill 4. Straightening machine 5. Heat treatment ( if you want tensile strength, yield strength and elongation rate of steel bar to be improved, this machine should be add ) 6. Flying sheart (the cutting length on the basis of your setting from 1.3-12mm, its speed 1.5-3m/s, below 16mm reinforced steel bar can be cut )7. Flip rack collecting rebar in straigaht, spool taking up mahcine collecting rebar in coil.8. Integrated control cabinetThe line speed is 1.5-3m/s and can be adjusted. The capacity will depend on diameter of rebar from 2t/h to 8t/h. |

my account

my account

log out

log out

my account

my account

log out

log out