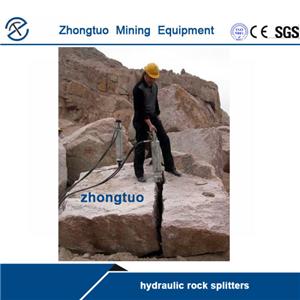

| Message: | Description of Hydraulic rock splitters:

The Hydraulic rock splitters consists of two parts: power units and the splitter. The working principle of the splitting machine is that the ultrahigh pressure oil driven cylinder output from the pumping station has a great driving force and can be made by the mechanical magnification Direction cracked.

Removing road barriers

Concrete road barriers can be quickly broken for removal by using a hydraulic rock splitter. Pieces can be cut to sizes that can be handled. Only one drilled hole is required to break a section. Drill a hole on an angle(See Fig.A).The splitter is placed into the hole(Fig.B) and a break is made in a few seconds. The broken sections are easily removed without a lot of dust and rubble. This method speeds up work and cuts costs.

Removing road curbs

Concrete road curbs can be split to the level of a road bed with controlled hydraulic rock splitting. A hole is drilled into the the curb(See Fig.A).Note the angle of the hole. The splitter breaking horizontally shears the curb as indicated in Fig. B. This is a fast,easy way to remove concrete curbs to read level.

Features of Hydraulic rock splitter:

1 split process without vibration, no impact, no noise, no dust, split within a few seconds to complete

2 single machine maximum split force up to 480 tons, high efficiency, can control the split, demolition, split size accuracy

3 light weight, simple operation, easy maintenance can be carried out in indoor and narrow space can be used for underwater construction. url:http://www.ztmineequipment.com |

my account

my account

log out

log out

my account

my account

log out

log out