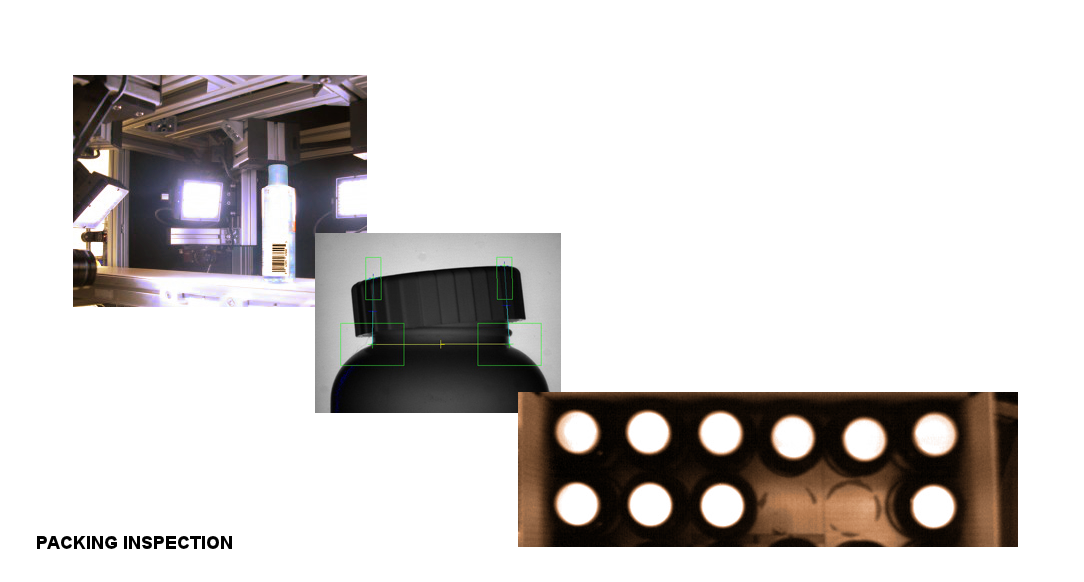

| Message: | Our applications not only detect presence or absence of product, they also verify orientation,positioning, count, number of multiple products.

Once presence / absence check is confirmed, the system can go forth and perform other relevant processes like performing vision inspection, rejection, diversion etc

NFD detection systems are primarily applicable to the pharmaceutical industry.Our online systems will check NFD-No Fill Detection system and camera system for rejecting defective packs on line. Our Liquid level inspection system inspects the fill level of the liquid. Sundaram’s liquid level inspection systems are your quality control supervisor. They detect empty and damaged bottles and discharge them from your production line. The vision system learns from a sequence of multiple images to obtain the best tolerance settings and compensate for runtime variations. Intelligent software significantly reduces the teach time by auto extraction of information. Simple operations through wizard for ease of use of the system during teach-in & productions. Intelligent Software is provided for quick and efficient learning of the sample products. Comprehensive production statistics and fault diagnosis.

• Recognition of the shape and position of components

• Detection of significant characteristics such as clips, foam rings or holes

• Identification of adhesive / seals on seams

• Recognition of glue volume and position!

• Measuring tasks viz: lengths, fold loss.

KEYWORDS :

packing inspection,

bottling machines,

packing of product,

packing work,

goods packaging inspection,

packaging machinery in india,

blister packaging india,

freight inspection,

packing inspection systems,

product inspection,

quality inspection,

packaging inspection,

packing machinery,

equipment packaging,

automatic filling machine,

industrial packaging machinery,

auto packing machine,

|

my account

my account

log out

log out

my account

my account

log out

log out