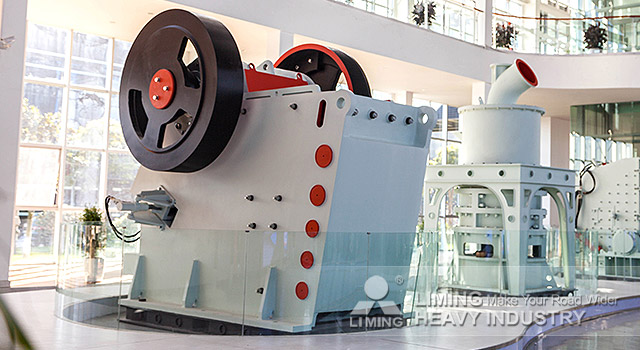

| Message: | PE jaw crusher use and use of

1, the series crusher is mainly used for metallurgy, mining, chemical, cement, construction, refractory materials and ceramics and other industrial sectors for coarse crushing and crushing a variety of medium hard minerals and rocks.

2, the series crusher crushing compressive strength of not more than 300MPa (MPa) of a variety of soft and hard ore, the maximum size of broken material shall not be greater than the provisions of the technical parameters table.

PE jaw crusher with a large crushing ratio, product size uniformity, simple structure, reliable, easy maintenance, operating costs and other economic characteristics. Jaw crusher is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industry and many other departments, broken compressive strength of not more than 320 MPa of various materials.

PE jaw crusher working principle

The working principle of this series of crushers is curved and extruding type. Its working principle is that the electric motor drives the belt and the pulley, moves the movable jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the bracket and moving jaw becomes larger, When the moving jaw down, the bracket and the moving jaw angle becomes smaller, moving the jaw in the rod, the role of the spring to move the jaw plate to the fixed jaw close to the same time, the material is crushed or broken pieces to achieve the purpose of breaking; , Leaving the fixed jaw plate, then broken material has been discharged from the crushing chamber under the mouth. With the motor continuous rotation and crusher jaw for periodic movement crushing and excretion of materials, to achieve mass production.

200 t / h Mobile crushing product line for a solid stone in Russia http://micrusher.com/en/case/407.html

Process diagram of limestone milling in Indonesia http://micrusher.com/en/case/416.html

|

my account

my account

log out

log out

my account

my account

log out

log out