| Message: | METAL JACKETED GASKET – GOOD RESILIENCE PRESSURES AND CORROSION RESISTANCE

Metal Jacketed Gasket consists of a soft filler encapsulated in a metallic material. The filler material provides compressibility and resilience while the jacket confers compressive strength and blow out resistance.

Metal jacketed gasket is specially designed and widely used for heat exchangers, autoclaves, columns, pressure vessels, flue stacks, boilers, gas mains, valve bonnets, pumps and similar services.

Most of metal jacketed gaskets are supplied in circular form but they can be manufactured to other shapes to suit individual requirements.

TYPES

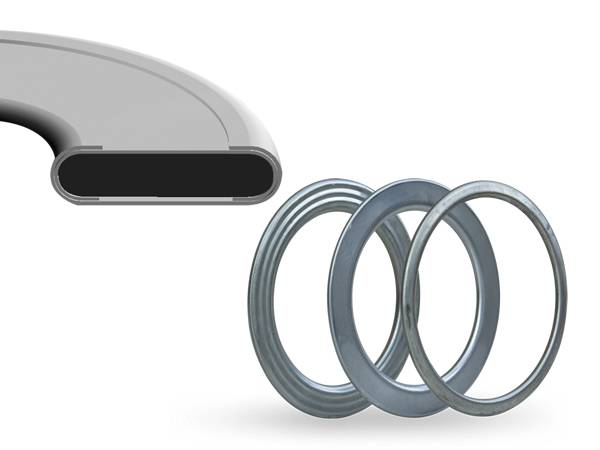

Single jacketed gasket. This type of gasket is used in air tool applications and engine applications where space is limited, gasket seating surfaces are narrow and relatively low compressive forces are available for seating the gasket.

Single jacketed overlap. Construction of this gasket offers more filler protection than the standard single jacketed design. It is especially useful for applications where the radial dimensions do not allow space for a double jacketed gasket.

Double jacketed gasket. Double-jacketed gaskets are probably the most commonly used style of gaskets in heat exchanger applications. They are also extensively used in standard flanges. Since most double-jacketed gaskets are custom made, there is virtually no limit to size, shape or configuration.

Double jacketed corrugated gasket. The double jacketed corrugated gasket is an improvement on a plain-jacketed gasket. The corrugations on the gasket will provide an additional labyrinth seal. Enhancing its compressive characteristics. Main sealing performance of double-jacketed corrugated gasket still relies on the inner lap. |

my account

my account

log out

log out

my account

my account

log out

log out